A global research team has created over 1,500 innovative thermal materials using AI, which could revolutionize energy efficiency in homes, offices, cities and even space.

A breakthrough in material design developed through machine learning and artificial intelligence, published in the journal Nature, promises to transform how we manage and utilize energy for cooling and heating.

Researchers from The University of Texas at Austin, in collaboration with Shanghai Jiao Tong University, the National University of Singapore and Umea University in Sweden, have developed more than 1,500 new thermal meta-emitters.

These advanced materials have the potential to make significant strides in energy efficiency and sustainability.

“Our machine learning framework represents a significant leap forward in the design of thermal meta-emitters,” study co-leader Yuebing Zheng, a professor in the Cockrell School of Engineering’s Walker Department of Mechanical Engineering, said in a news release. “By automating the process and expanding the design space, we can create materials with superior performance that were previously unimaginable.”

The research team’s new materials can selectively emit heat at varying levels and in different manners, offering unprecedented precision in cooling and heating.

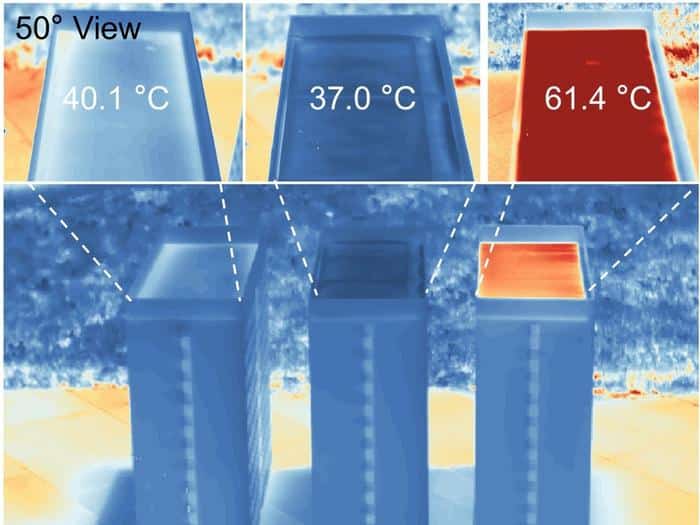

To test their innovation, the researchers fabricated four of these materials and applied one to a model house. When exposed to direct sunlight for four hours, the meta-emitter-coated roof was found to be 5 to 20 degrees Celsius cooler than roofs painted with conventional white and gray paints.

Caption: The middle building is wrapped with the researchers’ meta emitter materials. This structure showed lower temperatures than the other two, which used conventional paint, after sun exposure.

Credit: The University of Texas at Austin

According to the researchers, this cooling effect could translate to a yearly energy savings of 15,800 kilowatts in hot climates like those in Rio de Janeiro or Bangkok — significantly more than the 1,500 kilowatts a typical air conditioner uses annually.

Beyond cutting down on household energy costs, these thermal meta-emitters hold promise for broader applications.

They could help reduce urban temperatures by reflecting sunlight and emitting heat in specific wavelengths, thereby mitigating the urban heat island effect.

Additionally, in space, these materials could aid in managing a spacecraft’s temperature by efficiently reflecting solar radiation and emitting heat.

The labor-intensive and traditional trial-and-error methods in designing these materials have often led to suboptimal outcomes, hampering mainstream adoption.

“Traditionally, designing these materials has been slow and labor-intensive, relying on trial-and-error methods,” Zheng added. “This approach often leads to suboptimal designs and limits the ability to create materials with the necessary properties to be effective.”

The new machine learning platform overcomes these challenges by automating the design process of these highly complex three-dimensional structures, allowing for the creation of materials that can be integrated into everyday items, such as clothing, outdoor equipment and car interiors.

This advancement opens up numerous practical applications that could significantly boost energy efficiency and comfort in various sectors.

“Machine learning may not be the solution to everything, but the unique spectral requirements of thermal management make it particularly suitable for designing high-performance thermal emitters,” added co-author Kan Yao, a research fellow in Zheng’s group.

The research team aims to further refine their technology and apply it to additional aspects of nanophotonics — the study of light and matter interactions at the nanoscale.