Credit: Courtesy of the researchers/MIT

As the ongoing surge in COVID-19 cases strains the capacity of global healthcare systems, universities around the world are stepping into the fold to help fulfill the urgent need for ventilators.

The disease caused by the novel coronavirus is already pushing hospitals around the world to their limits. Hospitals in various areas of the United States are short on virtually everything from masks to manpower. Perhaps the most pressing issue for healthcare servicers is the shortage of ventilators. Ventilators, which deliver air via tubes to the lungs of patients, are a crucial tool in treating the aggressive respiratory disease.

Similar to pneumonia, the coronavirus attacks the respiratory system, filling the lungs with fluid and making it difficult for patients to breathe. Only the most severe COVID-19 cases — some 2.3 percent of patients — require ventilators, but those who do will die without them.

There are some 160,000 ventilators in the United States. While the capacity has not been reached yet, some hospitals in the worst-hit areas are getting close. In the past week, some New York hospitals have resorted to “ventilator sharing,” where two patients are treated with the same ventilator.

Internationally, the hardest hit health care systems have been dealing with similar resource issues. In Italy, some hospitals have been forced to ration care, directing resources away from older patients and those with a lower chance of survival.

In anticipation of worsening shortages, the private and public sectors have mobilized to produce ventilators at scale. Auto companies, including Ford, Tesla and GM, have begun converting manufacturing plants to produce ventilators. And Tesla will ship extra FDA-approved ventilators to hospitals within its delivery region worldwide for immediate use, without charging for either the device or delivery, Elon Musk tweeted two days ago.

A number of universities in the United States and around the world have initiated projects to design low-cost ventilators that can be built and distributed quickly. The projects vary in approach but all share the goal of increasing access to emergency ventilation systems in areas where there are shortages. Utilizing household items, products that can be found at hardware stores, Arduino boards and common medical items, these DIY-style, low-cost ventilators could end up saving lives.

Here’s a look at some of the ventilators being produced at universities around the world:

- Rice University

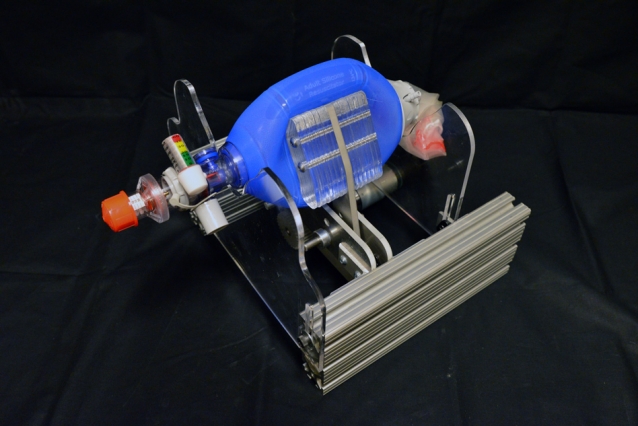

At Rice University, a team of students and engineers working in collaboration with Canadian global health design team Metric Technologies have created an automated bag valve ventilator system that costs only $300 to produce.

The ventilator consists of a mechanical device that squeezes a standard bag valve mask. Commonly used by emergency personnel when performing CPR, bag valves are typically operated manually: the operator squeezes the bag, pushing air into the lungs of the patient. They are effective at delivering air to patients but are difficult to operate by hand for more than a few minutes at a time.

The system produced by Rice University researchers automates this process.

In the prototype, a mechanical device built primarily from 3D-printed and laser cut parts compresses the bag valve. Using an Arduino board, the device can be programmed to adjust the rate of air delivery to the lungs to match the needs of different patients.

Future versions of the device are expected to include additional motors and sensors to further regulate the flow of air to the lungs. As of now, the device is not intended to replace larger ventilators currently used to treat patients in critical condition.

“The immediate goal is a device that works well enough to keep noncritical COVID-19 patients stable and frees up larger ventilators for more critical patients,” Amy Kavalewitz, executive director of Rice University’s Oshman Engineering Design Kitchen, said in a news release.

- University of Florida

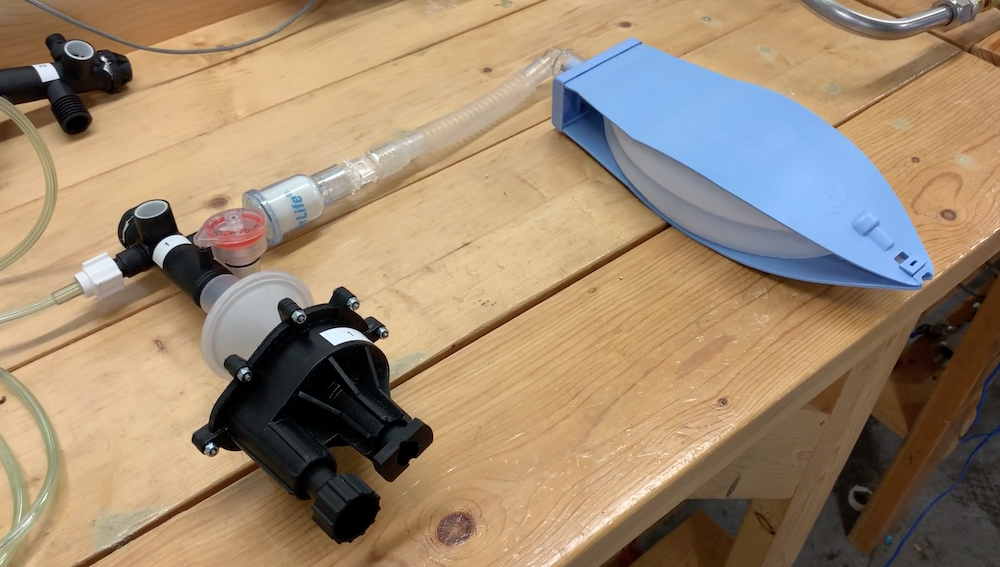

At the University of Florida, researchers designed an open-source, low-cost ventilator prototype using common hardware supplies, including PVC water pipes and lawn-sprinkler valves.

The project has been spearheaded by longtime UF anesthesiology processor Samsun Lampotang in coordination with UF simulation engineer David Lizdas and Gordon Gibby, an electrical engineer and former UF professor of anesthesiology.

Their DIY ventilation system uses a transistor driver that can be powered by a standard ham radio DC power supply and an Arduino-based control software that can be used to precisely adjust the respiratory rate.

The team is currently working on developing safety features to meet regulatory requirements. Details on the ventilator, including an open-source diagram and software repository, are available via a website created for the project, enabling anybody with the resources to recreate the DIY ventilator.

In all, the machine can be built for as little as $125 to $250.

- University of Illinois at Urbana-Champaign

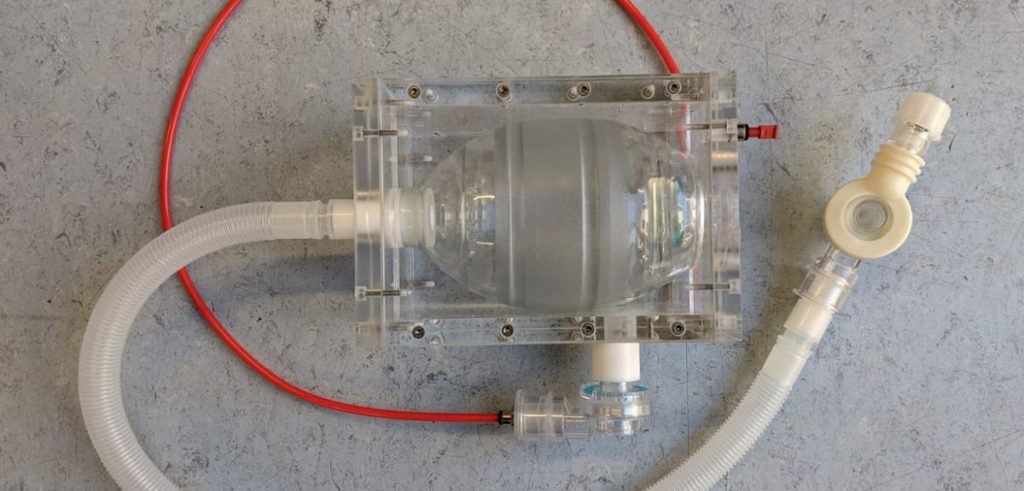

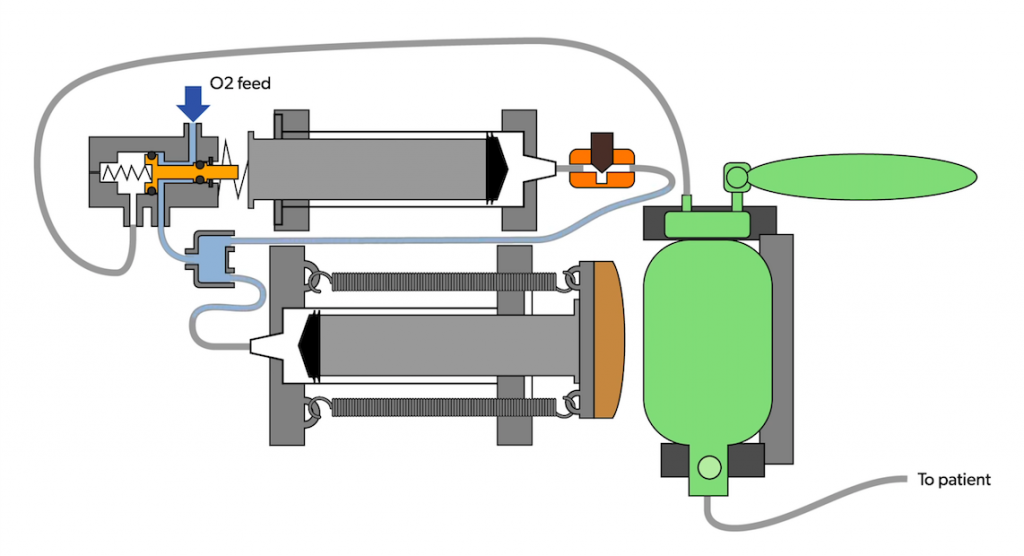

At the University of Illinois at Urbana-Champaign, a team of more than 40 researchers has developed the “Illinois RapidVent,” a working prototype for an emergency ventilator for COVID-19 patients.

The Illinois RapidVent can plug into a readily available oxygen source or a tank of oxygen and provide patients with pressure-controlled oxygen at regular intervals. The prototype has so far run for more than 75 hours, or more than 125,000 breathing cycles, and its performance is equivalent to that of commercial ventilators.

- University of Minnesota

Researchers at the University of Minnesota are in the process of developing a scalable, low-cost ventilator system designed for rapid deployment to healthcare providers.

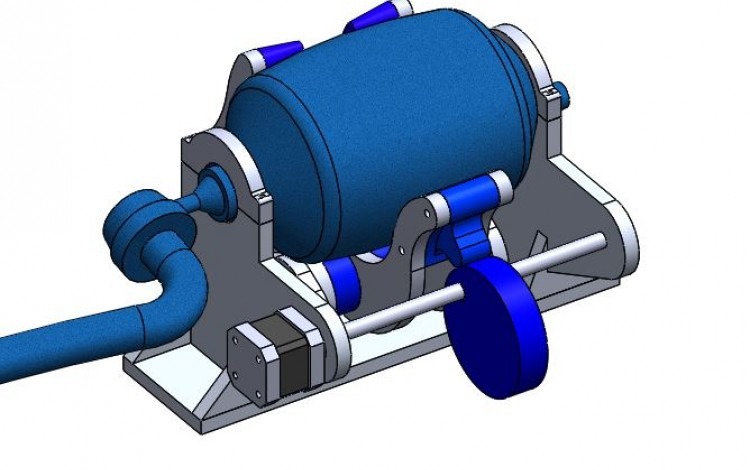

The system includes a frame that can be metal-stamped, 3D-printed or built from modified consumer goods, and a mechanical actuator that automatically pumps a bag valve.

- Massachusetts Institute of Technology

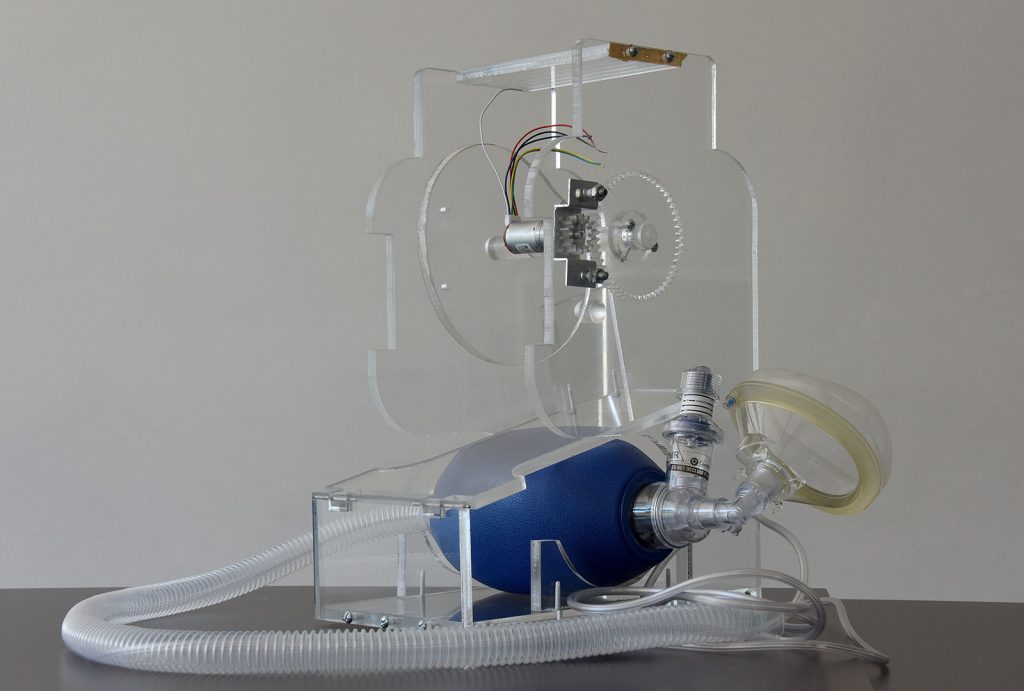

MIT is reopening a ventilator design project that started and ended a decade ago.

In 2010, a group of MIT students and faculty created a design for an emergency ventilator that, like the prototypes from Rice University and the University of Minnesota, utilizes a bag valve to pump air.

The original research team published a paper in the Journal of Medical Devices outlining the design but never actually produced the ventilator. After the COVID-19 outbreak began, volunteer engineers, physicians, and computer scientists at MIT reopened the project and are further building on the design for use with patients infected with the novel coronavirus.

The MIT design is expected to cost between $400 and $500 in parts.

The hope is that unconventional manufacturers such as auto companies can produce them on a large scale in short order. Like the other models, the device isn’t expected to replace ICU ventilators, but could be used in emergency situations or to free up other ventilators for needier patients.

- University of Oxford and King’s College London

Researchers at Oxford and King’s College London have developed an open-source ventilator that has been approved for government testing.

The model, dubbed OxVent, uses a bag valve to deliver air to patients and is composed of materials that are readily available in the National Health Service (NHS) supply chain.

The ventilator has been greenlighted for testing for safety and usability by the Medicines and Healthcare products Regulatory Agency (MHRA). If approved, OxVent will be produced by medical manufacturing company Smith and Nephew and could be available for widespread use within weeks.

- University of Costa Rica

The University of Costa Rica (UCR) has built an emergency bag valve ventilator based off of blueprints from the OxyGEN project in Spain.

The OxyGEN project’s respirator, designed by young engineers in Barcelona as COVID-19 broke out in Italy, was built out of wood and utilized a bag valve to deliver air.

UCR’s model, which has been dubbed Respira UCR, is not built from wood, but it has the same general structure as the OxyGEN ventilator, with tweaks to the design to make it more efficient and suitable for use by healthcare professionals in Costa Rica.

- Costa Rica Institute of Technology

At the Costa Rica Institute of Technology, researchers are developing two low-cost prototypes.

One of these prototypes is an original design by the School of Industrial Production Engineering for a mechanical ventilator built from low-cost 3D-printed acrylic parts.

The other design is based on a commercially available prototype that originated in England. It uses a set of pistons and adaptors to compress a bag valve that supplies air to patients. This design is low-cost and can be manufactured quickly.

Conclusion

Fighting off COVID-19 will require an international effort and contributions and sacrifice from people in all sectors of society. Thankfully, our university professors and research scientists are stepping up to the plate to deliver unique, visionary solutions to supplies shortages in this time of crisis.