Prosthetic limb technology has advanced greatly in recent years, but new designs can cost tens of thousands of dollars, leaving many amputees without affordable products.

Now, engineers at MIT have developed a low-cost, passive prosthetic foot that can be customized to fit the individual and mimic an able-bodied walk.

“[Walking] is something so core to us as humans, and for this segment of the population who have a lower-limb amputation, there’s just no theory for us to say, ‘here’s exactly how we should design the stiffness and geometry of a foot for you, in order for you to walk as you desire,’ ” Amos Winter, an associate professor of mechanical engineering at MIT, said in a statement. “Now we can do that. And that’s super powerful.”

The research has been published in the ASME Journal of Mechanical Design.

A new challenge

The MIT research began in 2012 when Winter was approached by Jaipur Foot, an Indian-based organization that manufactures artificial limbs.

It provides a passive prosthetic foot to people in developing countries and donates more than 28,000 models each year to prosthesis users in India and abroad.

For over 40 years, the organization has been making the same foot — a rugged, relatively life-like model that can allow users to perform tasks both outdoors and inside.

However, the model is fairly heavy and the internal structure is made by hand, which creates a variation in product quality.

Because of this, Jaipur Foot asked Winter if he could help design a better, more lightweight foot that could be mass-produced at a low cost.

“At that point, we started asking ourselves, ‘how should we design this foot as engineers? How should we predict the performance, given the foot’s stiffness and mechanical design and geometry? How should we tune all that to get a person to walk the way we want them to walk?’ ” Winter said in a statement.

Developing the foot

The researchers, led by former MIT graduate student Kathryn Olesnavage, first looked for a quantifiable way to relate the mechanical characteristics of a prosthesis to a user’s walking performance

While this relationship might seem obvious, it had never been fully formed.

This is because many developers of prosthetic feet focus on replicating the movements of able-bodied feet and ankles — a practice that doesn’t make much of a difference to someone who can’t even feel what the prosthetic foot does.

“One of the critical insights we had was that, to a user, the foot is just kind of like a black box — it’s not connected to their nervous system, and they’re not interacting with the foot intimately,” Winter said in a statement.

Instead, the researchers focused on designing a prosthetic foot that would produce lower-leg motions similar to those of an able-bodied walker, and thus, increase the amputee’s ability to walk.

“Prosthesis users in India and other developing countries typically want to appear able-bodied, to avoid stigmas associated with disability. This requirement is what made us explore ways to design the foot so it facilitates near able-bodied leg motion,” said Winter.

So, with this in mind, the team looked for ways to understand how the mechanics of the foot related to how the lower leg moves when the foot is in contact with the ground.

The researchers consulted an existing dataset comprised of measurements of steps taken by an able-bodied walker with a specific body size and weight. Previous researchers had recorded the ground reaction forces and the changing center of pressure experienced by a walker’s foot with each step, along with the position and trajectory of the lower leg.

The researchers then developed a mathematical model that describes the stiffness, possible motion, and shape of a simple, prosthetic foot.

Next, they entered the ground reaction forces from the datasat, which they could use to predict how a user’s lower leg would translate through a single step.

Using their model, they tuned the stiffness and geometry of the simulated prosthetic foot to have a minimal “lower leg trajectory error,” and produced a lower-leg trajectory that was close to an able-bodied mover.

Fine-tuning the product

The team then searched to find an ideal shape for a single-part prosthetic foot that would be simple and affordable to manufacture, while producing a leg trajectory similar to an able-bodied walker.

To do this, the researchers ran a “genetic algorithm” to search for the most desirable designs.

They created a ‘population” of feet, with different variables to make different curve shapes. Then they calculated their lower leg trajectory error, got rid of the ones that had a higher error, and mixed and matched the ones with a lower error to evolve toward an ideal shape.

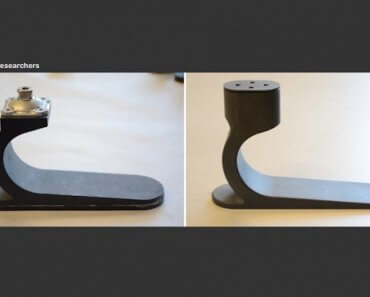

To do this, they used a wide Bezier curve to describe the shape of the foot, which in the end, looked similar to the side-view of a toboggan.

The researchers believe that, by tuning the stiffness and shape of the Bezier curve to a person’s body weight and size, they can produce a prosthetic foot specific to a customer that generates leg motions similar to able-bodied walking.

Finally, the researchers tested the design by producing several nylon feet for volunteers in India.

“Our research team visits our partners in India every six months to test prototypes and get feedback from their patients and doctors.” said Winter. “The patients who tried our foot were very excited about its energy storage and return ability, facilitating normal walking speed. One test subject ran around outside because he was so excited about it.”

The next step

After successful trials in India, the team has partnered with Vibram, an Italian company that manufactures rubber outsoles, flexible hiking boots and running shoes that look like feet.

“This summer we will be long-term field testing our foot with an integrated, over-molded cosmesis and high-wear sole designed by Vibram,” said Winter. “We are exploring the best business model to commercialize our technology. We are not far from commercialization, I would guess not more than a few years, but it is important that we do our due diligence to ensure the product is robust and meets users’ needs before we release it.”

Additionally, the research has been funded by the US Department of Defense to make a prosthetic foot for soldiers who were injured and who want to return to active duty, as well as for veterans who lead an active lifestyle.

“We are exploring how to tune our foot for multiple walking scenarios that would be important to this demographic, like rough terrain and up and down slopes. We are also exploring how to make easily customizable feet for individuals, such as through 3D printing,” said Winter.

Winter also added that the ability to use the body size and weight of a person to design a customized foot for an individual will be particularly important for women, since female amputees often have to use feet that are too big or too stiff for them.

Overall, the team hopes to create a prosthetic foot that can offer amputees an able-bodied walking performance at a low cost.

“Our aim is to create prosthetic foot technology that offers similar walking performance as products available in wealthy markets, but at a fraction of the price and affordable for the tens of millions of lower limb amputees in the developing world,” said Winter.

“We hope that our feet can facilitate mobility, employment, and full integration into society for this population by providing a product that is rugged, culturally appropriate, and facilities near able-bodied walking motion.”