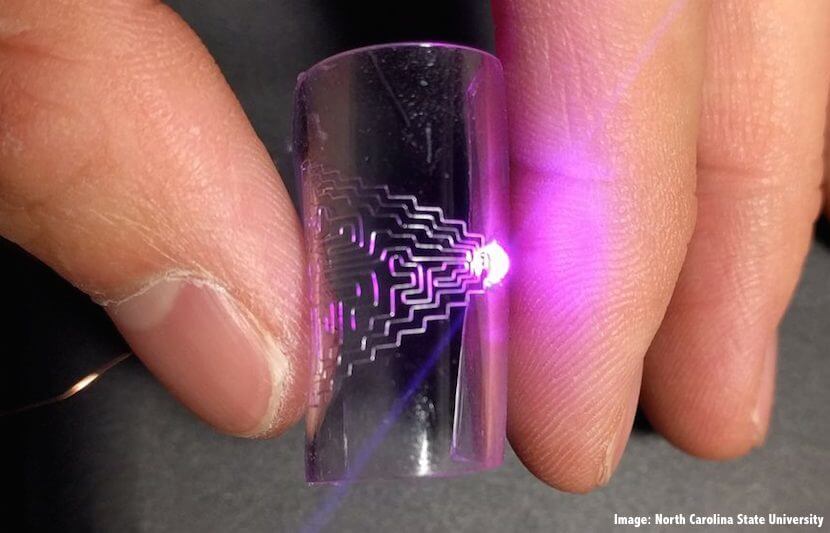

A team of researchers from North Carolina State University (NC State) has developed a method to create flexible, stretchable electronics capable of self-healing by directly printing metal circuits.

The technique is applicable with existing manufacturing systems that require direct printing technologies, and can be used with multiple metals and substrates.

The paper, “Electrohydrodynamic (EHD) Printing of Molten Metal Ink for Flexible and Stretchable Conductor with Self-Healing Capability,” is published in the journal Advanced Materials Technologies.

The lead author of the study is Yiwei Han, a Ph.D. student at NC State.

“Traditional printing methods for flexible electronics have many limitations in material cost, conductivity of the printed features, and printing resolution,” said Jingyan Dong, associate professor in NC State’s Edward P. Fitts Department of Industrial & Systems Engineering, and corresponding author of the paper. “In this research, we studied an EHD printing approach to achieve high-resolution printing of metal alloys for low-cost direct fabrication of metallic conductors.”

The researchers’ low-cost approach should offer an efficient way to make high-resolution circuits that could be implemented into commercial devices, Dong said in a statement.

While traditional EHD printing techniques use ink, the team’s new approach uses molten metal alloys that can melt at temperatures as low as 60 degrees Celsius. In their study, the researchers demonstrated their technique by directly printing three different metal alloys on four substrates. One substrate was made of glass, one of paper, and two of stretchable polymers.

“The EHD printed microscale metallic conductors represent a promising way to create conductive paths with metallic conductivity and excellent flexibility and stretchability,” said Dong.

After testing the resilience of the circuits on a polymer substrate by bending them 1,000 times, the researchers found that its conductivity was unaffected. They continued to test the resilience of the circuits by stretching them to 70 percent tensile strain, and the circuits were still proven to be electrically stable.

Most importantly, in the event that the circuits were damaged, the researchers discovered that the circuits are self-healing.

“Due to the low melting point of the metal alloy ink, the printed metal circuits can be recovered from failure simply by heating the device above the eutectic temperature of the metal ink to make metal flow back together,” said Dong.

“With their excellent conductivity, stretchability, self-healing, and high-resolution direct writing capabilities, the EHD printed metallic conductors may be applied in broad applications in stretchable electronics, wearable sensors and communication devices,” he said.

By using their technique, the researchers developed a high-density touch sensor capable of fitting a 400-pixel array into one square centimeter.

“Touch sensors or touch panel will become important input devices or sensors for many state of art electronics,” said Dong. “With high-resolution direct patterning capability from EHD printing, a high-resolution and high-density touch sensor array can be fabricated providing much better sensing resolution than that from traditional printing approaches.”

The researchers next plan on determining the capabilities of the metal printing in applications with stretchable electronics, wearable sensors, and communication devices.