Heart failure is a major problem afflicting about 26 million people around the world. In the U.S. alone, about 6.5 million people suffer from heart failure, and the the number is projected to rise to 8 million by 2030, according to the American Heart Association. When heart failure reaches end stage, heart transplant may be the only effective treatment.

Unfortunately, there is a shortage of donor hearts. While more than 5,000 heart transplants take place around the world each year, the number of approved transplantation candidates is estimated at more than 50,000. What’s more, many more people who need a new heart are not considered and approved as transplantation candidates due advanced age, cancer history, or other pre-conditions. Consequently, many receive ventricular assist devices (heart pumps). Others die waiting for a heart transplant.

The need for a well-functioning artificial heart is therefore critical.

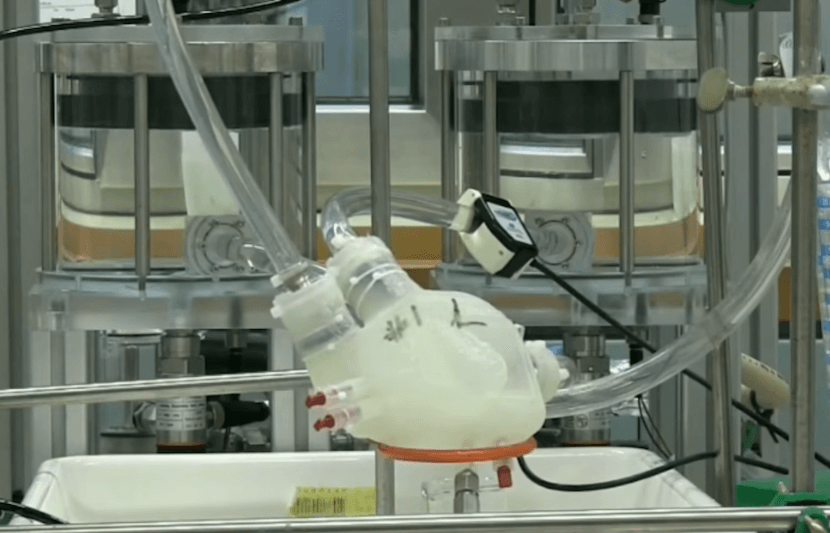

Now, researchers from the ETH Zurich Functional Materials Laboratory have a potential solution. They have developed a soft artificial heart that looks, and beats, like a real heart.

The soft artificial heart was created from a single block of silicone, using a 3D-printing method that allowed the researchers to create a complex inner structure.

Like a human heart, it has a right and a left ventricle. But unlike a human heart, in which the two ventricles are separated by a septum (wall of muscle), the right and left ventricles in this soft artificial heart are separated by an additional chamber. This chamber mimics the muscle contraction of the human heart; it fills and deflates to create the pumping action.

The creator of this soft artificial heart is Nicholas Cohrs, a doctoral student at ETH’s Functional Materials Laboratory, which is led by Wendelin Stark, a professor at ETH Institute for Chemical and Bioengineering and chair in Functional Materials Engineering.

The research team also includes Anastasios Petrou, a doctoral student at the ETH Product Development Group, who led the testing of this soft artificial heart.

The test of the prototype heart shows that it works and moves like a human heart. It is limited to 3,000 beats (about 30-45 minutes) for now, so it not ready for implantation.

“This was simply a feasibility test,” Cohrs said in a statement.

“Our goal was not to present a heart ready for implantation, but to think about a new direction for the development of artificial hearts.”

The research is published in Artificial Organs.

What inspired the development of the soft artificial heart?

The University Network (TUN) spoke with Cohrs to find out.

“We came up with the idea of a soft heart from nature,” Cohrs said.

“My boss Prof. Stark sat down with Prof. Volkmar Falk, now the head of surgery of the Deutsches Herzzentrum Berlin (German Heart Center Berlin), and learnt about artificial blood pumps.”

Blood pumps, unfortunately, have several drawbacks.

“They are rigid machines, which give a continuous blood flow, which does not have anything to do with the native human heart,” said Cohrs.

“Therefore, there are a lot of problems associated like hemolysis and thrombosis. They thought about how it is possible to give a more natural artificial heart and came up with the idea of a soft heart. So, the main idea really comes from nature itself, or how to best copy nature’s functionality.”

Once the idea was conceived, it took Cohrs and his team about 1.5 years to develop the soft artificial heart.

“In collaboration with the clinicians, we designed the heart on the computer using the CT scan of a real human heart,” Cohrs said.

“We printed the mould and manufactured the heart. The difficulty was to find a proper drive for the heart, to mount the heart valves, etc.: the smaller things. Also testing took more time than we had expected. In total, maybe 1.5 years from the idea to having tested the heart on the test bench.”

Now that the prototype has been successfully tested, the research team will work on optimization.

“We need to improve the lifetime significantly by trying a new material and optimization of the geometry to have a heart, which we are confident to implant,” said Cohrs.

Cohrs finds the project appealing, and is motivated to improve on it.

“I like my project a lot, because I can work in an interdisciplinary team with people, who really know, what they are talking about,” he said.

“Of course it is also very motivating to work on something, which really affects people and hopefully some day may improve the life of many patients, which suffer from this disease.”