Physicists at the University of Sussex in England have developed a new technology that could resolve the persistent problem posed by brittle smartphone screens.

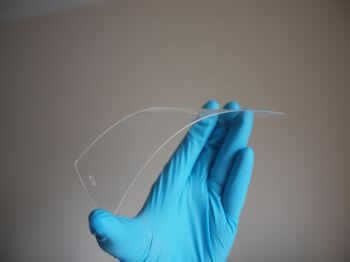

This new technology, which combines silver nanowires with a two-dimensional carbon material called graphene, could be used to produce smartphone screens that are “cheaper, less brittle, and more environmentally friendly.” The technology could also lead to development of devices that are more energy-efficient, more responsive and tarnish-proof.

The paper is published in Langmuir.

The problem with current smartphone screens lies not just in their brittleness, but also in their high manufacturing costs and the resulting damage to the environment. Currently, smartphone screens are made primarily with indium tin oxide, which is both brittle and expensive. Extracting Indium, which is a rare metal, also has an impact on the environment. While silver could be used instead of indium tin oxide, it too is expensive. Another drawback of using silver is that the metal tarnishes when exposed to contaminants in the air.

The new technology avoids all these issues without sacrificing performance.

This is the first time that a hybrid material has been used for smartphone screens.

“While silver nanowires have been used in touch screens before, no one has tried to combine them with graphene,” Professor Alan Dalton, from the university’s School of Mathematical and Physical Sciences, said in a statement. “What’s exciting about what we’re doing is the way we put the graphene layer down. We float the graphene particles on the surface of water, then pick them up with a rubber stamp, a bit like a potato stamp, and lay it on top of the silver nanowire film in whatever pattern we like.”

Because the technology could be easily scaled, the researchers believe it could lead to the demise of brittle smartphone screens.

“It would be relatively simple to combine silver nanowires and graphene in this way on a large scale using spraying machines and patterned rollers,” Dalton said in a statement.

This means that brittle mobile phone screens might soon be a thing of the past.

Combining the two materials results in superior performance and energy savings.

“We think that this new approach is really exciting,” Dr. Matthew Large, lead researcher on the project within the university’s School of Mathematical and Physical Sciences, told The University Network (TUN). “We are able to use tiny amounts of silver and graphene to make a coating which performs far better than either on their own. On top of that, all of our processing is done at room temperature using low-energy processes; the standard material, indium tin oxide (ITO), needs to be deposited at high temperatures to get the very best performance. In this way we make a big energy saving.”

The combination also reduces production costs of smartphone screens significantly.

“The combination of graphene with the silver nanowires also makes for a dramatic materials cost saving,” Large told TUN. “The price for the existing technology is somewhere near $50-100 per square metre. Silver nanowire-based technology is now competitive with that; however when we add graphene (which costs cents by comparison) the amount of silver we need falls and we can now make comparable coatings at $5-10 per square metre.”

Even though the new technology involves the use of silver, tarnish would not be an issue as the graphene layer protects the silver nanowires from contaminants in the air.

Another advantage of the hybrid material is that its flexibility does not hamper performance.

“What we’ve also seen is that when we bend the hybrid films repeatedly the electrical properties don’t change, whereas you see a drift in the films without graphene that people have developed previously,” Large said in a statement.

This paves the way towards one day developing completely flexible devices.

The process hasn’t all been easy, though.

“In terms of the technology itself, it has been a fairly straightforward development from our understanding of the nanomaterials we are using,” Large told TUN. “The bigger roadblock for the technology is the fact that it is disruptive; in order to tempt industry away from existing technologies we have to show very significant benefits. That’s why we’ve looked to drive the costs down using abundant materials and cheap, low-energy processing methods.”

Despite these difficulties, the researchers have high hopes for the future of their new technology.

“We are working with partners in industry to understand the scalability of our approach, both on the materials supply side and manufacturing side,” Large told TUN. “We believe that the cost of this new technology is sufficiently low that there may by uptake in industry over the coming years, but we are always looking for other partners to work with us to bring the technology forward.”